For company Hašpl a.s. is quality important same as to our customers. Therefore we subject the goods passing through our company to a thorough inspection. At the same time, we send the goods to accredited laboratories, which perform tests in accordance with current legislation. After receiving the test results, we compile the necessary documents accompanying the goods.

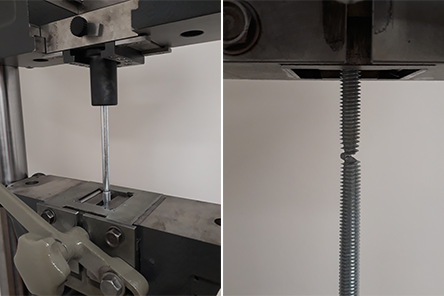

To verify mechanical and physical properties of goods we are using testing machine ZD 10/90 - maximum load 100 KN with modernized drivers and TIRAtest software.

During the tensile test, we verify whether the product meets the prescribed values defined in the relevant standards such as:

- tensile strength – Rm, min (MPa /mm2)

- maximum breaking force – Fmax (N)

- verify the prescribed test load - Fp (N)

- verify the prescribed minimum test load Fm, min (N)

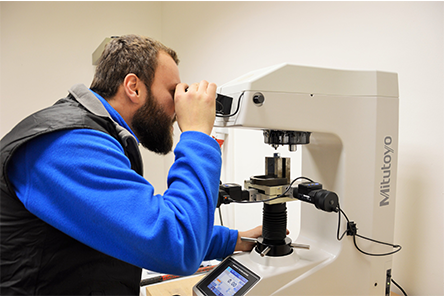

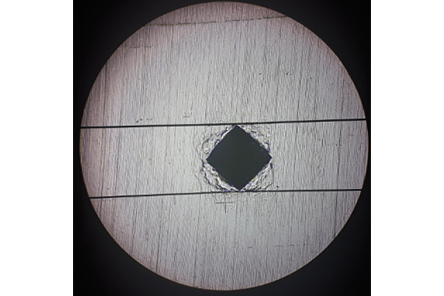

We made a Vickers hardness test on the Mitutoyo HV-100 hardness tester with a range of HV 0.3 – 30. We have the possibility of software conversion to a Brinell, Rockwell and other standards…

We verify the quality of heat treatment of the product:

- we measure the surface hardness

- we measure the hardness of the core

- we will perform a decarburization test

- we will perform a carburization test

We prepare the surface on a metallographic grinder before measuring the the hardness

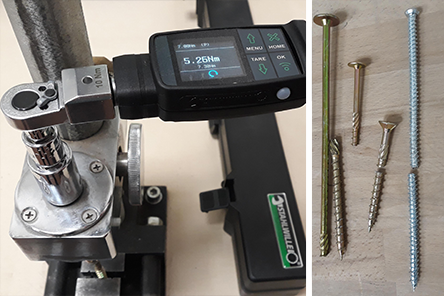

We undergo our screws to a destructive test by measuring the torque up to breake with a Stahwille digital wrench.

We measure the layer of galvanic zinc, hot-dip zinc and other surface treatments by "Elcometer 456" and "Fisher Phascope".

We verify the fabrication of threads with thread gauges.

We check all dimensions and save measured values in databases, including information about the batch and supplier. Than we evaluate this data and assess the supplier for further cooperation.

Only products that meet all requirements will be released for our customers.

We are constantly expanding the equipment of our control based on the requirements of the growing assortment. Whether by purchasing new measuring machines or by constructing new fixtures for existing equipment.

Despite our efforts, something went wrong? In this case, contact our complaints department or fill out the complaint form directly and we will quickly resolve your complaint.